2012 ISSUE 1

New Benchmark Set in Newcastle

Newcastle is a major port city on the east coast of Australia, which exports grains and other commodities. Like many cities, urban encroachment and revitalisation of the city centre and nearby suburbs, has put residential and commercial zones in close proximity to port terminals and facilities. Important trade-related activities such as quarantine and pre shipment fumigation of grains, occur there. These treatments are controlled in NSW by the EPA, which issues licences for emissions.

Newcastle Agri Terminal is a new facility to be constructed in 2012, which will significantly increase the capacity for grain exports from Newcastle.

The latest fumigant capture and dust suppression technology has been incorporated as part of their commitment to corporate social responsibility. Toxic gas emissions recently stirred considerable public debate, arising from accidental releases from the Orica chemical facility in Newcastle Port, which drifted across to Stockton and other nearby suburbs.

Nordiko is proud to be working with Newcastle Agri Terminal – demonstrating that export business – essential to trade and economic prosperity, can be successfully achieved whilst meeting the highest environmental and health and safety standards.

California Cold Storage Facilities – New Regulations Enforced

In March 2010, two Californian cold storage workers suffering from dizziness and headaches were diagnosed with suspected methyl bromide poisoning. The  source of the toxic gas was traced back to cold storage facilities which dealt with fruit that was off gassing methyl bromide (MB) resulting in atmospheres of up to 20ppm.

source of the toxic gas was traced back to cold storage facilities which dealt with fruit that was off gassing methyl bromide (MB) resulting in atmospheres of up to 20ppm.

As a result of the incidents, the California Department of Pesticide and the United States EPA enforced regulations that help mitigate worker exposure to harmful levels of MB. Nordiko, in conjunction with Cardinal Professional Products developed an effective solution employing large activated carbon filters that could capture methyl bromide inside the facilities. Once depleted, the filters undergo a special treatment process where the carbon is able to be reused therefore reducing costs of buying replacement carbon.

For the initial 3 months of the season, the Nordiko/Cardinal filtration systems have proved effective in keeping the methyl bromide concentration low, to the satisfaction of customers and regulators alike.

Nordiko is proud to support this new application in the USA for recapture, and hopes to continue growing in the region. Nordiko’s partner, Cardinal Professional Products, are leaders in fumigation products and services and have proven to be an invaluable partner.

Nordiko Quarantine Systems—starting to count

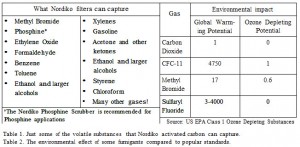

Nordiko Quarantine Systems has been operating for over 10 years, and since its establishment has been providing solutions to prevent the release of many harmful gases. Though gas capture is often for the sake of human health and safety, the environmental impacts of some fumigants can be quite severe.

Methyl Bromide, a very common fumigant and one that Nordiko deals with the most, is both a greenhouse gas (Global Warming Potential of 16) and an Ozone Depleting Gas (Ozone Depleting Potential of 0.6).

Nordiko is proud to say that in the last year their products have prevented the release of over 2 tonnes of methyl bromide in Australia, and approximately 6.5 tonnes worldwide. This is the equivalent of preventing the emission of 111 tonnes of CO2 or 3.3 tonnes of the ozone devastating CFC-11.

Another fumigant known for its environmental effect is sulfuryl fluoride, which possesses a GWP of 3-4000; so every tonne of sulfuryl fluoride released has the equivalent effect to 4000 tonnes of carbon dioxide.

Nordiko’s methyl bromide emission reductions come from the use of over 68 degassing systems, employing the Nordiko activated carbon filter.

However Nordiko filters are not only limited to post-fumigation applications, they are also employed in residual gas extraction. In this application they capture a wide range of toxic gases which can be found in shipping containers as the result of past fumigations or chemicals released by commodities (see table below).

Phosphine for the win

In October last year Nordiko set up a phosphine fumigation and scrubbing system for Pioneer as part of their seed fumigating operations in Iowa, USA.

The system consists of a customised 20 foot chamber that is pressure tight (>1.5 times the standard) and connected to a phosphine dispensing system as well as a Nordiko Phosphine scrubbing system.

The Nordiko Phosphine scrubbing system scrubs exhaust phosphine at high efficacy and due to its design can be run for many fumigations without the need to replace the filter medium.

Unfiltered emissions of toxic fumigants such as phosphine can pose a real health risk to nearby workers and communities, depending

upon concentrations and dispersion patterns. By the use of a scrubbing system Pioneer have shown health, safety and environmental leadership and responsibility.

Sydney Markets—Environmental Leadership

Sydney Markets is a leading fresh produce market authority and has achieved significant recognition internationally for a series of environmental initiatives. This success story continues, with the introduction of fumigant gas capture technology, addressing the emission of toxic, ozone depleting gases to atmosphere. These gases can be a threat to nearby workers and can spread considerable distances depending upon prevailing weather patterns.

success story continues, with the introduction of fumigant gas capture technology, addressing the emission of toxic, ozone depleting gases to atmosphere. These gases can be a threat to nearby workers and can spread considerable distances depending upon prevailing weather patterns.

Southern Cross Produce have installed the Nordiko recapture system to their fumigation chamber, in anticipation of the increased need for methyl bromide fumigations, due to the banning of chemical dipping with dimethoate and fenthion in Australia. Fumigation is a necessary quarantine treatment for the inter-state and international transport of many types of fresh produce. By using Nordiko recapture technology, important trade requirements can be met, without endangering health or the environment.

Residual gas on the nose

The issue of residual gases in shipping containers has been well known for some time, however addressing the issue has been challenging.

Usually when the safety of unpacking shipping containers is considered focus is mostly on fumigants such as methyl bromide, phosphine and sulfuryl fluoride—all of which have been added for quarantine and pre- shipment purposes. However the shipped goods themselves may also be releasing potentially harmful gases.

Gases such as formaldehyde, benzene and cyanide may be present in goods either as residues from manufacture or decomposition products of materials.

Though this gases may not be present in levels as high as many fumigants, they may still be exceeding allowed exposure levels, and in some cases these gases may be potentially more toxic.

Nordiko has witnessed an increase in commercial interest surrounding the presence and hazard of residual gases. This has mostly been through work involving the detection, identification and ventilation of non- fumigant related residual gases in shipping containers—a service Nordiko Quarantine Systems provides.

The following table lists just some of the residual gases that may be found in shipping containers, possible sources and their safe levels:

| Gas | Potential Sources | Maximum recommended exposure concentrations |

| Formaldehyde | Glues, resins, solvents, foams, rubber, latex | 0.1-5ppm |

| Benzene | Glues, paints, wax, detergents, thinners, solvents, inks, adhesives, coatings, plastics, nylons, resins | 0.5-5ppm |

| Ammonia | Dyes, cleaners, cotton materials, some paints | 25-50ppm |

| Hydrogen Cyanide | Sometimes used as a fumigant, resins, acrylics , acetonitrile and some nylons | 1.9-10ppm |

| Acetonitrile | May be released by polyurethane foams | 20-40ppm |

| Toluene | Solvents, explosives, dyes | 20-50ppm |

| Dichloroethane | Plastics (PVC), furniture, upholstery, automobile parts, housewares | 1-10ppm |

Source: NIOSH Pocket Guide to Chemical Hazards http://www.cdc.gov/niosh/npg/

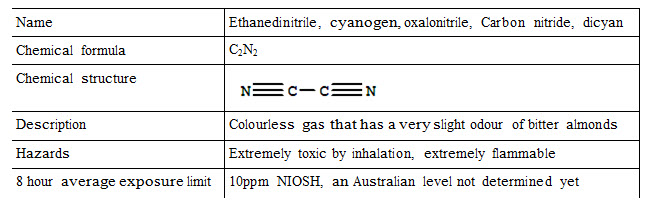

Ethanedinitrile—New Gas On The Block

Despite its efficiency and economy there is an

ongoing search to replace methyl bromide as a fumigant due, at least in part, to its ozone depleting potential. Ethanedinitrile (EDN) is a new candidate that was created by the CSIRO to replace methyl bromide in soil fumigations.

During CSIRO testing in soil fumigations the gas showed to require lower doses (and exposure times) to have the same affect as methyl bromide on common soil insects, nematodes and fungi.

These tests showed breakdown quickly in soil to produce harmless bi-products. This is an advantage for worker safety, but also means that the time interval between fumigation and replanting is shortened, increasing productivity.

The 8 hour time weighted average (TWA) for ethanedinitrile is 10ppm, twice the value for methyl bromide, despite a lower dosing concentration. This is a huge advantage for public and worker safety since the chance of toxic exposure is decreased two-fold.

A replacement for methyl bromide in soil fumigations will also have an important environmental impact. The global warming potential and ozone depleting potential of both ethanedinitrile and its decomposition products are meaning no greenhouse or ozone hole contributions.

Pre-plant soil treatment is a significant fumigant application where recapture is technically challenging to apply. If EDN (like carbon saturated with recaptured QPS MB), replaces methyl bromide use in soil fumigation, the environmental and safety issues of the remaining QPS and CUE applications can be mitigated by the use of scrubbing technology, removing methyl bromide’s threat to the atmosphere.

Like all toxic gases, Nordiko recommends capture technology to minimise emissions and achieve the best health and environmental standards.

Meet the Team: Graeme Simpson

Graeme Simpson has been a director of Nordiko since its inception, and is now Joint Managing Director (Administration) of Nordiko’s parent group – Asiaworld Shipping. A fully qualified accountant, Graeme helped set up Nordiko’s patent family, and is in charge of financial affairs for both Nordiko and Asiaworld, supported by his capable team, in Sydney head office.

Graeme Simpson has been a director of Nordiko since its inception, and is now Joint Managing Director (Administration) of Nordiko’s parent group – Asiaworld Shipping. A fully qualified accountant, Graeme helped set up Nordiko’s patent family, and is in charge of financial affairs for both Nordiko and Asiaworld, supported by his capable team, in Sydney head office.

Together with Ken Fitzpatrick, Graeme provides professional guidance and direction for Nordiko’s business, and is always available for commercial advice on Nordiko’s many activities.

Graeme lives close to Sydney head office, saving on commuting time common in many cities. Together with his wife Mary, Graeme enjoys music, bushwalking, swimming – and watching cricket – a favourite past-time for many Australians!

Speak Your Mind